Software

For Exceptional Measurement Accuracy and Unparalleled Analytical Versatility

from R&D to Full-Scale Production

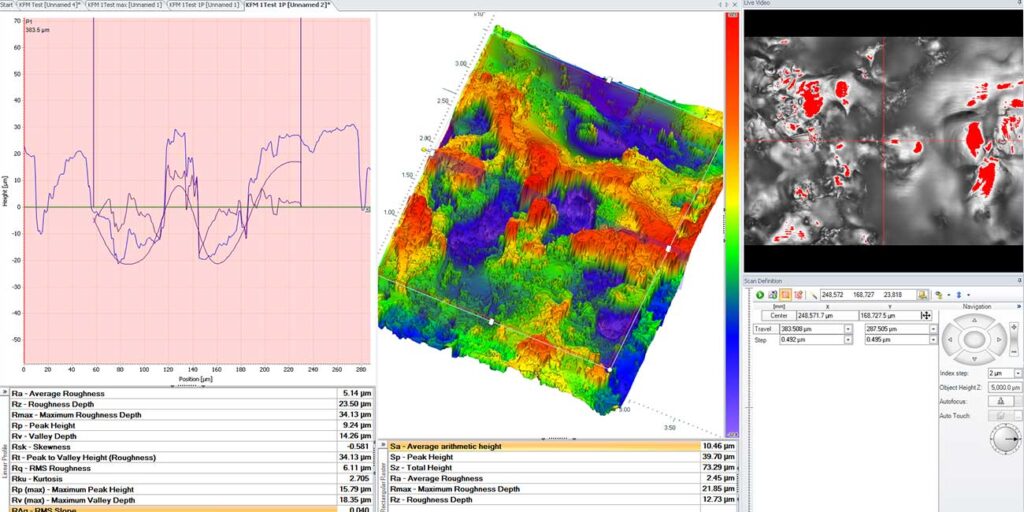

The powerful metrology software for manual measurement and analysis of your samples. User-friendly and equipped with over 500 built-in analysis and data operations.

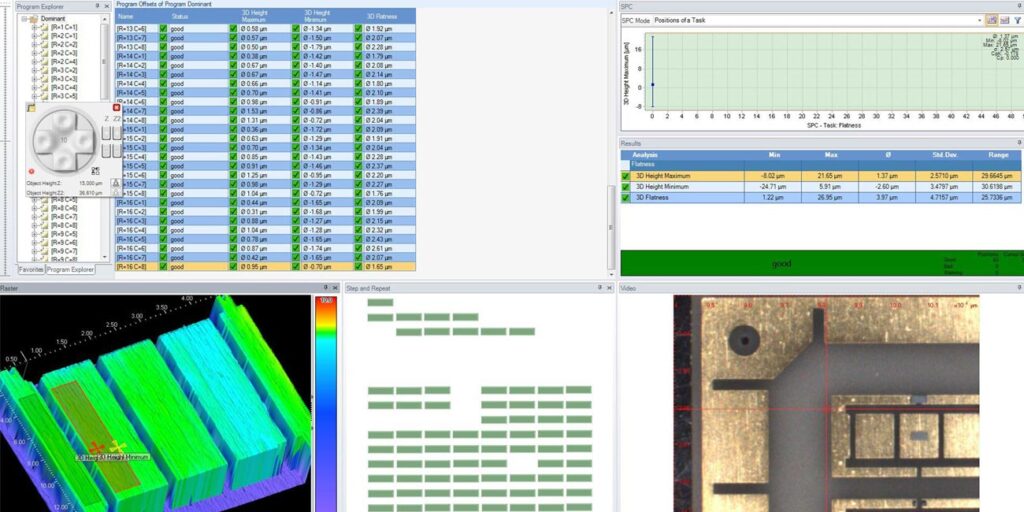

The software to fully automate your measurement and analysis process with automated fiducial correction, step & repeat to measure complete batches and clear result indication.

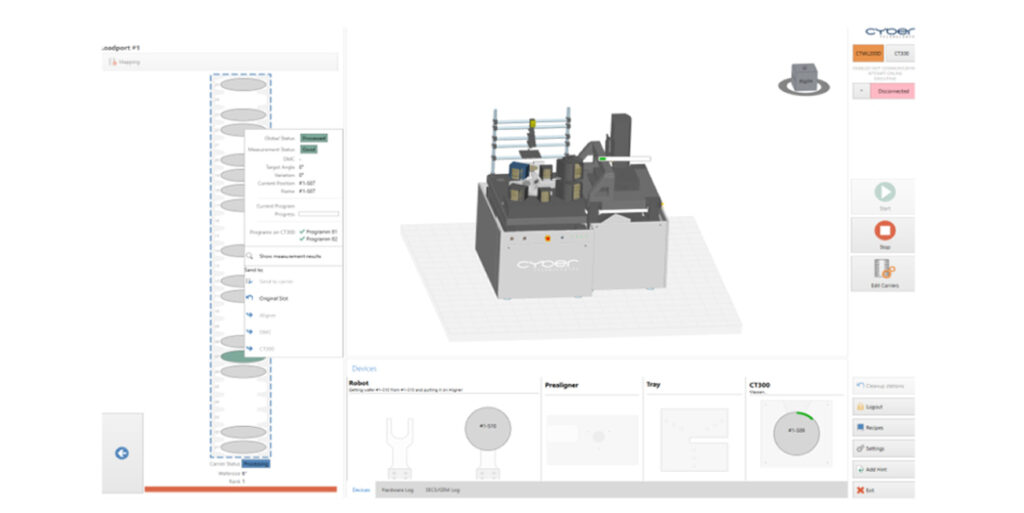

Production software for metrology systems and sample handling. Take full control over samples, handling, measurement and results. Connect via SECS/GEM (optional) and more.

General

cyberTECHNOLOGIES GmbH

Georg-Kollmannsberger-Straße 3

85386 Eching-Dietersheim

Germany